(GERMANY)

End-of-line packaging machines and palletization for the packages of:

– Chemicals

– Pharmaceuticals

– Cosmetics & Body care

– Food & Beverage

COMPLETE SOLUTIONS

ALL-IN-ONE-SOLUTIONS

an all-in-one solution based on standard modules can cover

all these steps to automate you entire end-of-line packaging process.

ETT Packaging Modules

FORMING

Before the product can even find its way into

the case, the cardboard blank has to be

opened and tightly sealed at the bottom.

ETT’s tray and case formers do this job in a

fast and reliable process.

PACKING

The powerful modular top loading

robot is the central element of each ETT

packaging system. Tried and tested

state-of-the-art drive technology

ensures fast and precise case loading of

a wide range of products.

SEALING

The sealer is one of the last stations in the

end-of-line packaging process, before the

goods packed in cases get on their way to

the customer. Whether using hot glue or

tape – the packed case has to be tightly

sealed before leaving the end-of-line

packaging machine

COVERING

The lidder places a lid on the filled

case to prepare it for dispatch to the

retail trade. Thanks to their universal

design, the ETT lidders can handle

both U-lids or cover trays.

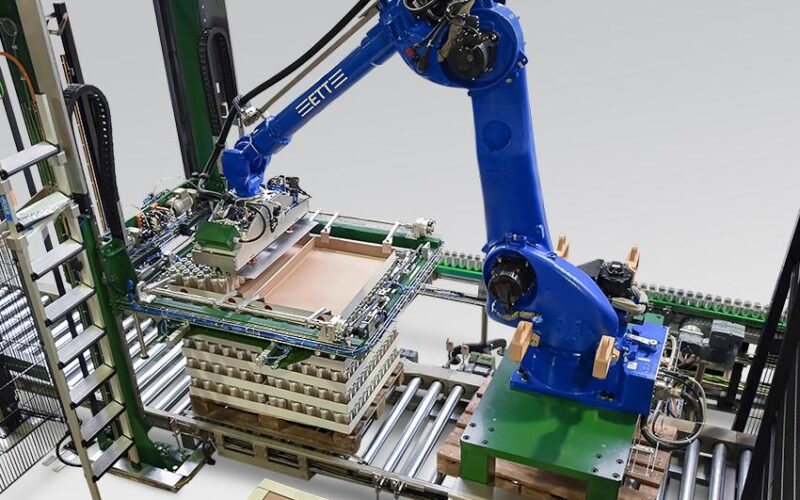

PALLETIZING

The palletizers stack the finished cases

onto the transport pallet to ensure

that your goods remain safe and

undamaged during transport.

Compact integrated solutions from

ETT with small capacities

ROBOBLOCK

Designed as a complete solution, the Roboblock consists of a

compact machine chassis with an integrated robot-based pick &

place packing module and a case forming and sealing module.

Thanks to its very low space requirements, high versatility and

favourable price it is the perfect system for your entry into the

world of automation.

- Speed up to 7 or 12 cases per min

- Sealing methods Self-adhesive tape or hot glue

- Your benefits optionally available with fully automatic changeover function

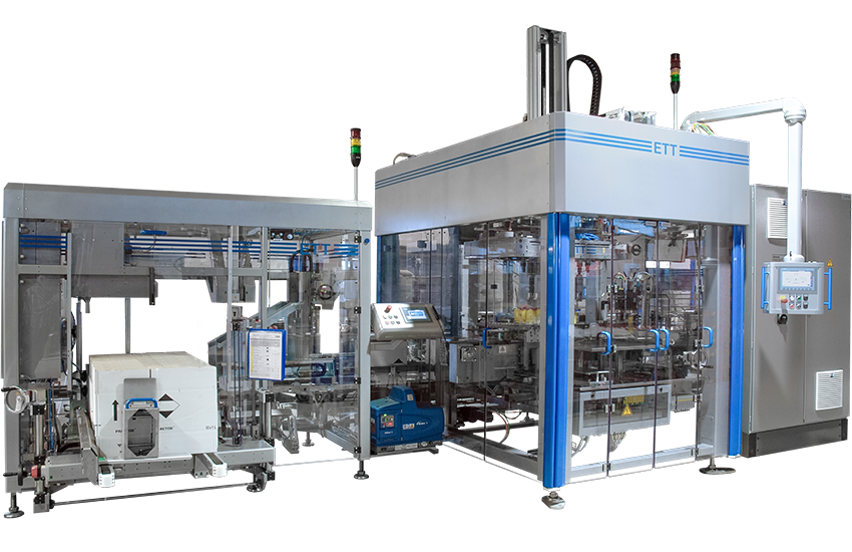

MONOBLOCK-PACKER

The Monoblock Packer consists of a two-axis packing module, a

case forming and a case closing module. Thanks to its compact

monoblock design it can be used even in confined spaces.

- Speedmax. 14 Kartons/Min.

- Sealing methodsSelf-adhesive tape or hot glue

- Many different collating units for a wide range of products

- Universal gripper heads with quick-change grippers to ensure fast changeover

- Gripper head rotating unit – for maximum flexibility

COMPACT PACKING SYSTEM

Placed directly next to each other, the three individual modules

case former, pick & place packer and case sealer operate “hand

in hand”.

- Speed up to 20 cases per min.

- Sealing methodsSelf-adhesive tape or hot glue

- Special features Different types of ETT-collating units available for integration | different case former and sealer models available | each individual module can be replaced if required | optionally available with a robot packing module

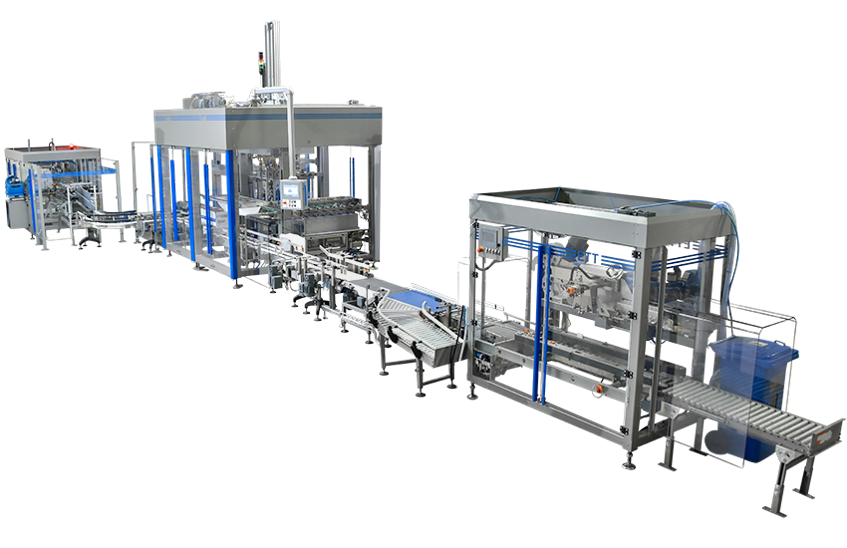

HIGH-SPEED PACKING SYSTEM

Case former, pick & place packer and case sealer, with buffer

sections between the individual machines, are combined into a

complete solution based on tried and tested standard modules.

- Standard speedup to 60 cases per min.* | up to 360 products per min.

- Sealing methodshot glue

- Your benefitscompatible with all ETT-collating units | all case forming and sealing methods are basically available | each individual module can be replaced | optionally available with a robot packing module.

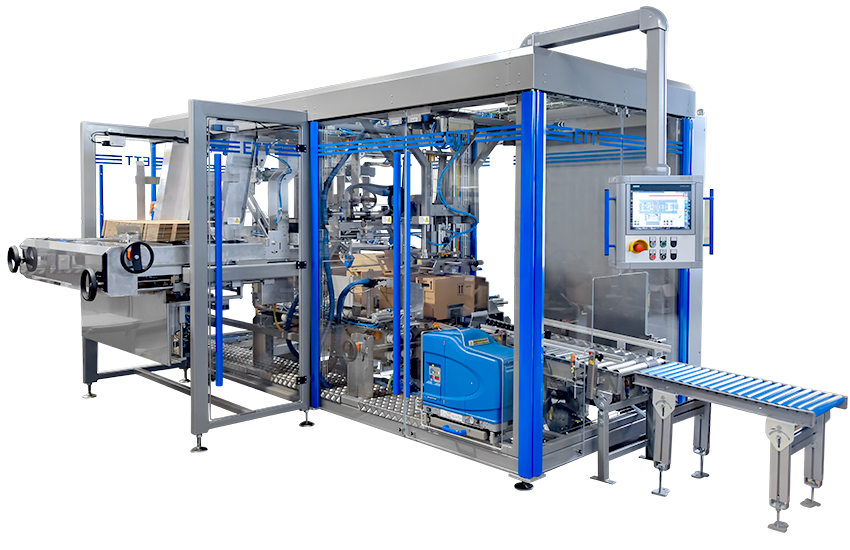

WRAPAROUND PACKER

Thanks to a wide range of standard supply and grouping

systems as well as a great variety of special solutions, the

wraparound packer can process products of various types, sizes

and shapes.

- Standard speed up to 30 cases per min.

- Sealing methodshot glue

- Special Featuressuitable for full-wrap packaging and trays | optionally available for producing tray/hood packaging (up to 20 cpm) | intermittent operation

CHEMICALS

WASHING AGENTS & DETERGENTS

BODY CARE

PHARMACEUTICALS

FOOD & BEVERAGES

لا تعليق